When considering the best butterfly valves for sale, choices can be overwhelming. These valves are crucial for regulating flow in various systems. From industrial plants to residential plumbing, their role cannot be overlooked.

The market offers a range of options, each with distinct features. Quality and price vary significantly. It's essential to evaluate what you truly need. Some may prioritize cost over quality, which can lead to issues later. You might find a cheap option, but will it last?

Investing in the right butterfly valves for sale is vital. Think about the long-term benefits. A well-made valve can save you from frequent replacements and repairs. Reflect on your specific requirements and make an informed choice. Remember, the right valve can enhance efficiency and reliability in your systems.

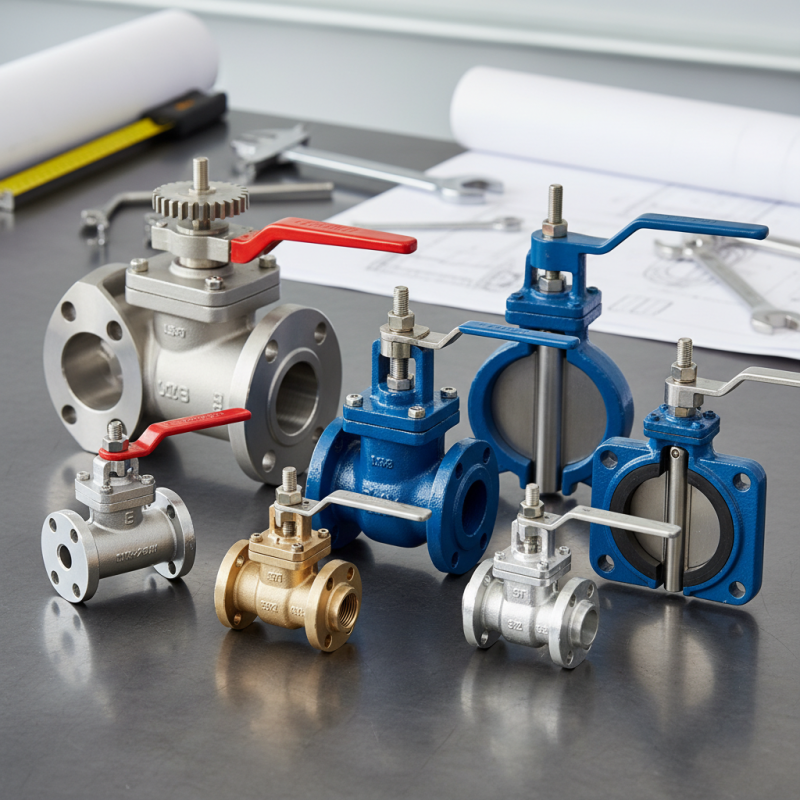

Butterfly valves are essential components in various industries. They control the flow of fluids efficiently. Understanding the types can help you make better choices. There are two main categories: resilient seated and high-performance. Resilient seated valves are commonly used for water services. They offer low torque and cost-effectiveness. High-performance valves, on the other hand, are ideal for chemicals and high-pressure systems.

According to industry reports, the global butterfly valve market is growing. It's expected to reach over $7 billion by 2026. This growth indicates a rising demand for efficient fluid control systems. Various industries, such as oil and gas, water treatment, and food processing, heavily rely on butterfly valves. However, selecting the right type requires careful consideration.

Material choice matters greatly. Common materials include cast iron, stainless steel, and PVC. Each has its benefits and drawbacks. For instance, stainless steel is durable but more expensive. PVC is light and corrosion-resistant, yet it may not withstand high temperatures. Understanding the differences in these materials can help. Many people overlook specific application requirements, leading to suboptimal performance. Looking deeper can yield better insights and choices.

When selecting butterfly valves, understanding key features is essential for making an informed choice. The construction material is one critical aspect. Butterfly valves can be made from metal, plastic, or rubber. Each material offers different strength, weight, and corrosion resistance. Choosing the right one depends on the application's demands. For instance, metal valves are robust but heavier, while plastic valves are lighter but may not withstand high pressure.

Furthermore, size and configuration play significant roles. You must ensure the valve fits the pipeline correctly. Standard sizes vary, and misfits can lead to inefficient operation. The design should be compatible with existing systems. Additionally, consider the actuation method. Manual, electric, or pneumatic systems each present unique advantages. Manual operation can save costs, but automatic options may enhance efficiency.

Lastly, check the pressure rating and flow characteristics. These specifics help anticipate how the valve performs under various conditions. It’s easy to overlook this aspect, but it can lead to unexpected failures. Selecting a butterfly valve requires thoughtful reflection on your project’s precise needs. Finding the right match is not always straightforward; it may take time and research to sort through options.

This chart represents a comparison of key features to consider when selecting butterfly valves. The features evaluated include Material, Pressure Rating, Size Range, Temperature Range, and Seal Type, each rated on a scale from 0 to 10. A higher rating indicates a more favorable characteristic for valve selection.

When selecting the best butterfly valves in 2026, several key brands dominate the market. Each brand offers a unique set of features. The materials used can vary widely. Metal or plastic construction impacts durability and cost. It’s essential to assess your specific needs. Think about the application—water, air, or chemicals.

Additionally, the size and pressure ratings matter greatly. Some valves perform well under high pressure. Others are better for low-pressure systems. Installation ease can also differ significantly between brands. Some products require specialized tools, while others are user-friendly.

Despite thorough research, you may find unexpected challenges during installation.

Comparative analyses often reveal inconsistencies among customer reviews. Not every product lives up to its claims. Performance may vary, even within the same brand. It's wise to look for patterns in feedback. Some users report failures after only a few months. Others have long-term satisfaction. Understanding these complexities will help you make an informed choice.

Pricing trends for butterfly valves are evolving rapidly. According to a recent market report, the global butterfly valve market is projected to grow at a CAGR of 4.5% from 2023 to 2026. This upward trend reflects increasing demand across industries, such as water treatment and oil and gas. As we approach 2026, buyers can expect prices to stabilize, but some fluctuations may still occur due to material costs.

Material selection significantly impacts pricing. For instance, valves made from stainless steel often command higher prices than those made from plastic. The report highlights that raw material costs could rise by 3-5% annually due to supply chain challenges. While some manufacturers may absorb these costs, others will pass them on to consumers. This shift could vary dramatically across different regions and sectors.

In addition, technological advancements are changing the pricing landscape. Many new models incorporate smart technology, which can increase the initial cost. However, the long-term savings from improved efficiency might offset these higher upfront prices. As buyers consider their options, understanding these trends will be critical. Investing in energy-efficient products could lead to better returns, despite the apparent initial costs.

Proper maintenance of butterfly valves is essential for their longevity and performance. Regularly inspect the valve seals and body for wear and tear. Check for signs of corrosion or damage that could affect functionality. A simple visual inspection can save costly repairs in the long run. Cleaning the valve regularly is also important. Remove any debris that may accumulate on the seats or disc.

Lubrication plays a critical role in maintaining optimal performance. Use the right type of lubricant for your specific valve to ensure smooth operation. Infrequent lubrication can lead to stiffness and malfunction. Pay attention to the actuator as well. If it’s not responding correctly, it might need adjustment or replacement.

Don't overlook operating conditions. High temperature or pressure can affect valve integrity. Monitor the performance continuously to identify any abnormalities. Addressing small issues before they escalate is a wise choice. Neglecting these details can lead to failures. Regular maintenance and attention to detail will enhance the reliability of your butterfly valves.

| Valve Size | Material | Pressure Rating (psi) | Temperature Rating (°F) | Application | Maintenance Tips |

|---|---|---|---|---|---|

| 2 inch | Cast Iron | 150 | 180 | Water Supply | Regularly lubricate the shaft and check for leaks. |

| 4 inch | Stainless Steel | 200 | 250 | Chemical Processing | Inspect seals regularly and clean to prevent corrosion. |

| 6 inch | PVC | 140 | 120 | Irrigation Systems | Check for cracks and ensure proper alignment during installation. |

| 8 inch | Aluminum | 150 | 200 | HVAC Systems | Lubricate periodically and ensure the operator is functioning smoothly. |