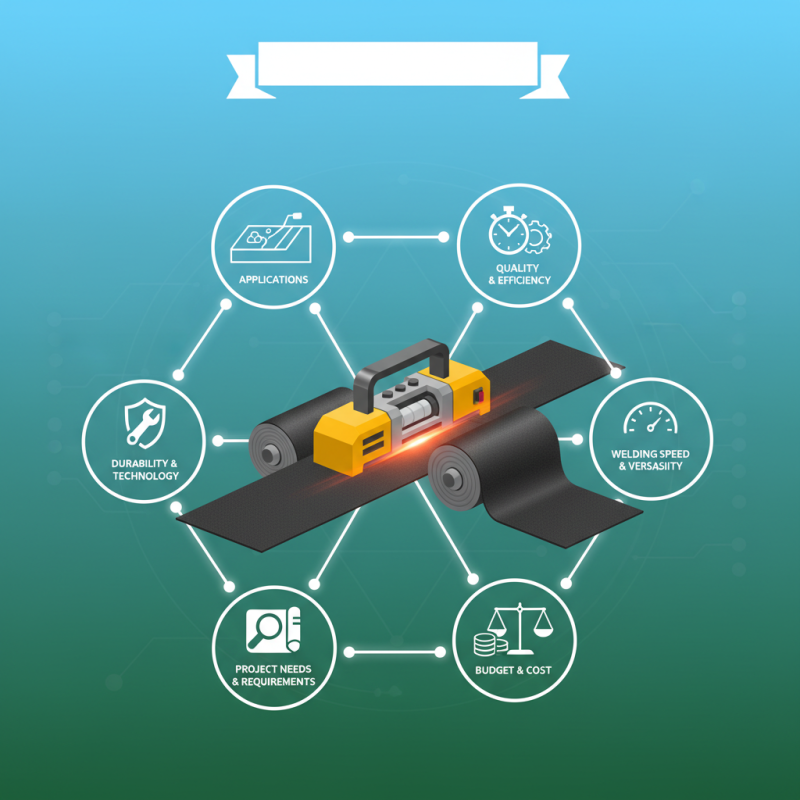

Selecting the right geomembrane welding machine is crucial. The right machine ensures quality and efficiency in projects. This decision impacts both time and costs.

A geomembrane welding machine is vital for various applications. It is used in landfill liners, ponds, and pools. Therefore, knowing what to look for is essential. Quality, durability, and technology are key factors. Consider the machine's welding speed and versatility.

Sometimes, it may feel overwhelming to make this choice. You might question the features and your project needs. Each project has unique demands, leading to uncertainty. It's important to reflect on your specific requirements. Balancing features with budget constraints is also necessary. Making the right choice can lead to success and reduced waste.

Geomembrane welding machines play a vital role in various applications, including waste containment, mining, and water management. These machines create strong, waterproof seals to prevent leakage. According to recent industry reports, the global geomembrane market size reached over $2 billion in 2022. This growth reflects increasing demand for reliable infrastructure, particularly in waste management sectors.

Selecting the right welding machine requires understanding its capabilities. Many machines utilize hot air or extrusion welding techniques. Hot air welding is popular for its speed and efficiency. However, extrusion welding provides superior strength for larger projects. These machines can be complex, and users may face a learning curve. Training is essential to maximize their potential.

Research indicates that improper machine operation can lead to significant failures. A study found that 20% of geomembrane installations fail due to poor welding practices. Such failures can result in costly repairs and environmental damage. Therefore, careful selection and training are crucial in reducing risks and ensuring successful project outcomes.

When selecting a geomembrane welding machine, several key features significantly impact performance and durability. The type of welding process is crucial. Hot air and extrusion welding are the most common methods. Each has unique advantages depending on the material and climatic conditions. For instance, hot air welding is more versatile, but extrusion welding provides a stronger joint in colder environments. Selecting the right process can increase efficiency by nearly 25%, based on a recent industry study.

Another vital factor is the machine's control system. Advanced machines come with digital controls and programmable settings. These features allow for consistent quality and adaptability to various geomembrane types. According to industry reports, machines with automated controls reduce human error by up to 30%. This is critical for projects with stringent quality standards. Moreover, portability matters. A lightweight machine can save time and labor costs, especially on large sites.

Budget considerations often lead to compromises. While it’s tempting to go for cheaper units, this can lead to higher long-term costs. Machines that are less durable may require more frequent repairs. Investing in a reliable machine may reduce operational downtime. This is especially important since reports indicate that delays can escalate project costs by up to 15%. Thorough research and understanding of these features can guide better decision-making in a competitive market.

When choosing a geomembrane welding machine, consider the following key features. The bar chart below illustrates the average importance rating of various features based on industry insights.

Selecting a geomembrane welding machine involves understanding industry standards and certifications. These standards ensure safety, quality, and reliability in various applications. For instance, the American Society for Testing and Materials (ASTM) offers specific guidelines for welding geomembranes used in landfills and ponds. Compliance with ASTM D welded seams can help prevent leaks and extend the membrane’s lifespan.

Certifications like ISO 9001 reflect a company's commitment to quality management systems. Research shows that organizations with ISO certifications can improve efficiency by up to 20%. This is crucial when considering the long-term performance of welding machines. Additionally, welding machines must meet specific safety standards, such as those published by the Occupational Safety and Health Administration (OSHA). Failing to meet these requirements can lead to accidents and costly repairs.

In the ever-evolving technology landscape, some manufacturers struggle to keep up. This can result in subpar products that compromise project integrity. Investing in a certified welding machine is not just important; it's essential for success. Companies should closely evaluate the certifications of welding machines before making a purchase. Balancing cost with standards can be challenging, but it is necessary for ensuring quality and reliability in geomembrane welding.

Selecting the right geomembrane welding machine can be challenging. One major aspect to consider is machine efficiency. Machines that use energy-saving technologies not only save costs but also enhance productivity. Look for machines that offer quick warm-up times, as this can significantly reduce downtime during projects.

Temperature control capabilities are crucial. Machines should have precise temperature settings to ensure optimal welding quality. A flexible temperature range allows for adjustments based on material specifications, which could prevent weld failures. Regularly calibrating temperature settings is vital, though it is often overlooked.

Tip: Always check user reviews regarding these features. Real-world experiences provide insights that specifications alone may not reveal. Also, consider the machine's ability to maintain consistent temperature during lengthy projects; fluctuation in heat can ruin welds. Aim for a machine that shows stable performance across different conditions.

| Feature | Importance | Recommended Range | Notes |

|---|---|---|---|

| Machine Efficiency | High efficiency reduces operational costs | Above 90% | Check for energy consumption ratings |

| Temperature Control | Ensures consistent welding quality | ± 5°C | Look for digital control options |

| Welding Speed | Faster welding increases project efficiency | 5-10 m/min | Speed may vary with material type |

| Weight and Portability | Easier transportation and maneuverability | Under 30 kg | Consider collapsible designs |

| User-Friendly Interface | Reduces training time and errors | Intuitive controls | Seek machines with touchscreens |

When budgeting for geomembrane welding equipment, costs can vary significantly. A report from the Geosynthetics Institute notes that equipment expenses can range between $15,000 to over $100,000. This wide margin often reflects the machine’s capabilities and technology. For small projects, a basic model may suffice. Larger sites often require advanced features, which can drive costs higher.

Consider additional financial factors. Training for operators can add another $2,000 to $5,000. There are also maintenance costs to factor in, averaging around $1,000 annually. A poorly maintained machine could lead to inefficiencies or failures, causing further expenses.

It's essential to assess long-term needs versus immediate requirements. Spending less on a basic unit might seem wise at first, but frequent repairs can accumulate. Balancing initial costs with potential future expenses is a complex yet necessary task. The outcome of your project depends heavily on this decision. Investing in more advanced technology could pay off in the long run, but be wary of overextending your budget.